Operational Excellence (OpEx) as a principle isn’t just a way of working, or a set of tasks an organization has to achieve. OpEx is a mindset. It’s a way of thinking that strives for excellence in all performance areas by incorporating a variety of principles, tools, systems and resources. And as a mindset, the focus of OpEx is on enabling the business – and the people in it – to excel using existing resources more effectively.

Achieving operational excellence doesn’t come easily though. Just ask the leaders at Ipsen Pharma Biotech, who began their OpEx journey in 2005. The company implemented lean-based practices using toolsets specific to the five operational units that formed part of their Pharmaceutical Quality System. Ipsen developed their own excellence model grounded in their vision of ideal employee behavior, and in supporting a culture of excellence. Their OpEx journey included multiple iterations and continuous improvement activities, which culminated in their achieving Operational Excellence across the Ipsen Group.

OpEx and Continuous Improvement: What’s the difference?

The concept of OpEx is often confused with that of “continuous improvement”. While the two are related, they aren’t the same.

OpEx is about developing an innovative strategy that will set a business on a path of continuous growth. It is focused on long-term change, and involves every member of the organization, at every level.

Continuous improvement is about incrementally improving existing processes, products, and services over time. It involves the business’ management setting goals in specific areas, and business units working together as teams to achieve those goals.

At its heart, OpEx is about improving the value you deliver to your customers by making sure you apply your resources as effectively as possible. Continuous improvement resides within OpEx, creating and refining processes that help your business achieve its strategic goals.

What an OpEx framework looks like

There are several schools of thought on what an OpEx framework should contain, each with its own guiding principles. Here, we look at the two most prominent approaches, both of which thought provide a sound foundation for building your Operational Excellence framework.

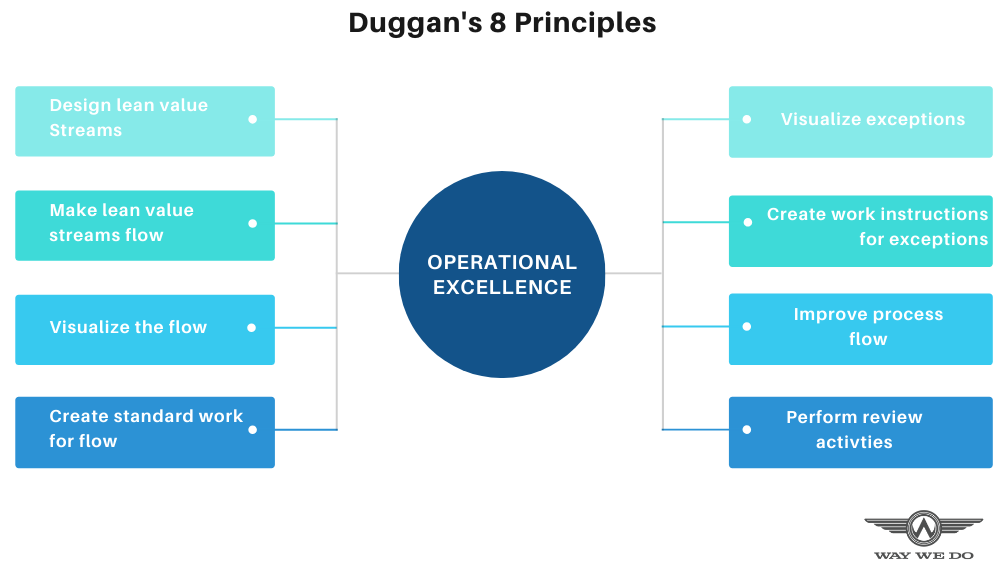

Duggan’s 8 Principles

These principles focus on providing value by improving visibility and the flow of work.

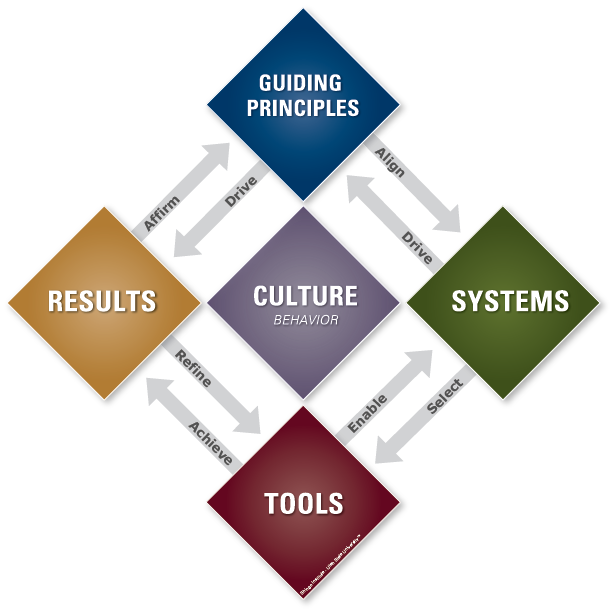

The Shingo Model

The Shingo Model states that to achieve Operational Excellence, organizations must:

- have a workforce willing to embrace change

- embrace continuous improvement practices

- understand that cross-functional collaboration is vital, and

- ensure all activities align closely with the overall business strategy.

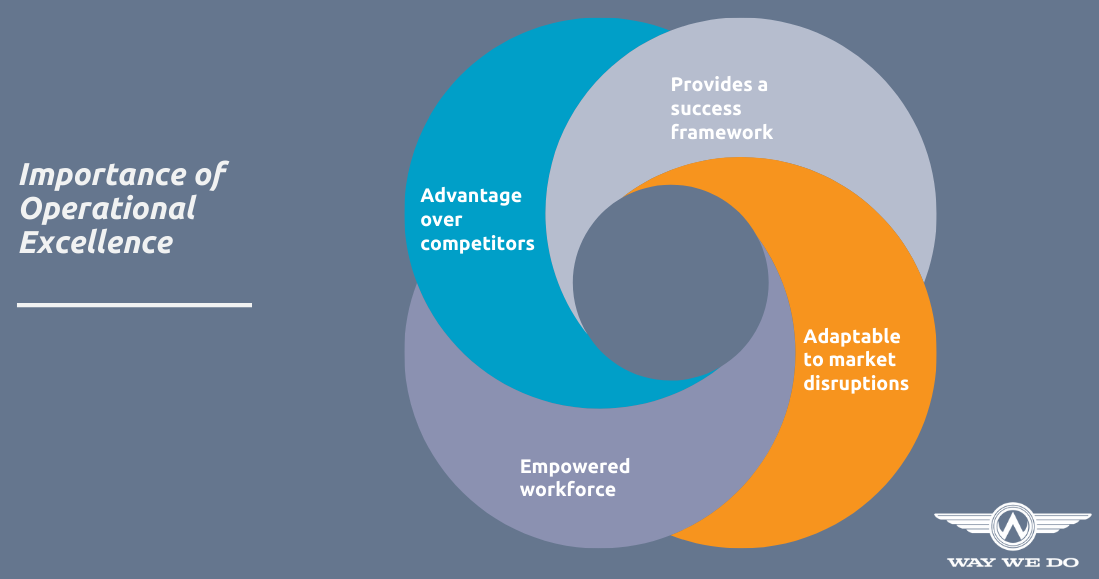

Why is OpEx important for an organisation?

The benefits to be had from embarking on an Operational Excellence journey for your organization are many and varied. Here are our Top Three.

1. It gives you an added advantage over your competitors

As we mentioned earlier, OpEx is about making use of your current resources and applying them more efficiently so you can perform better. Any efficiency boost is going to have impacts large and small on your business. The one you’ll likely notice most is increased productivity.

One of the principles in the Shingo Model is “to seek perfection”. While we will never be perfect, it’s still a worthwhile goal to strive toward. Seeking perfection means setting the bar high enough to create a mindset that is continually on the lookout for long-term, sustainable solutions, that won’t compromise your service quality.

For Boston Scientific Clonmel, their OpEx journey has seen their product shipments increase by 43%. Backorders decreased by 41%, and cycle times reduced by up to 80%, all of which has contributed to boosting their customer service quality.

2. It gives your organization a success framework for good times and bad

A solid OpEx framework makes you more adaptable to market changes. Customer preferences change, economies get disrupted, and new technologies come into the market all the time. By implementing your OpEx strategies, you’ll have the foundational skills you need to respond to these and any other market upheavals.

Regeneron Pharmaceuticals Inc. found that by following the principles of continuous improvement and implementing changes as they were realized, they were able to ensure zero supply disruptions, and increased lead times for receiving raw materials.

3. It helps you create an empowered workforce

OpEx involves every member of the organization, from the mailroom to the executive suite, by encouraging them to contribute their own insights and expertise. By tapping into the deep knowledge each of your employees have about their respective roles, you are ultimately creating better value for your customers.

OpEx creates a culture that’s open to new ideas, gives employees a sense of ownership in their work, and sets an expectation of responsibility for managing their daily tasks without interruption from the management.

Again using the Ipsen Biotech example, the company recorded an increase in employee engagement of 25% from the start of their OpEx journey, and a decrease in staff turnover to less than 1%.

Starting your own OpEx journey

Like we said earlier, OpEx doesn’t come easily, and it doesn’t happen overnight. To be successful, your organization needs to complete several activities effectively before it can claim excellence.

1. Build your OpEx team

Select a team of subject matter experts to become your organization’s Think Tank. Your OpEx team should be cross-functional, with members coming from the organization’s various business units – the size of your team will depend on your organization. They’ll be responsible for developing your improvement strategies, and facilitating their execution. Your OpEx team will also be responsible for analyzing the key aspects of your business, monitoring organizational performance, and fostering a culture of improvement.

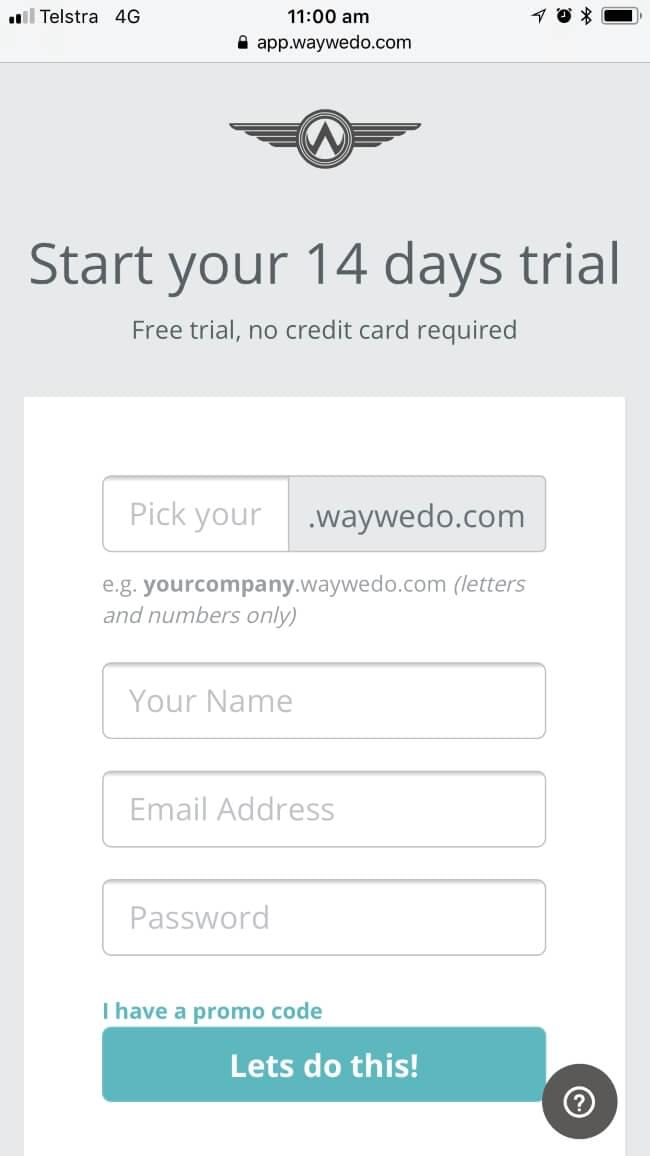

When creating your team, be sure to outline the members’ roles and responsibilities and share this information with everyone in your organization. Use your Way We Do account to create a new organizational chart. Using the default role description template will help you to present your OpEx team visually to your employees. All your staff will have access to the structure section for them to easily see who is on your OpEx Think Tank team.

2. Analyze your organization’s current state and identify opportunities to improve

To start an improvement journey, it’s vital you understand the state of your business’ current processes and performance. By analyzing your business where it’s at right now, you’ll gather foundational insights into what opportunities are available to improve and innovate. There are a variety of analysis tools and methodologies you can use. The most common come from Business Process Management, Lean, Six Sigma, Value Stream mapping, and Kaizen. You may opt for one or a combination of these to conduct your initial analysis.

You can access reports on team activity for specific processes from your Way We Do account. Information such as cycle time, which is recorded as part of completing processes in Way We Do, can give you process improvement insights and also identify areas where automation may prove helpful.

3. Determine your implementation strategies

The methodologies we mentioned earlier also recommend tactics you can use to execute on the improvement opportunities you’ve identified. A key area for implementing improvements will be in your processes, and with Way We Do making these improvements is an easy task.

For instance, you may have identified an opportunity to reassign certain tasks to a new division, or integrate business applications using third-party connectors. Way We Do’s well-defined Activated Checklist structure and format allows for reassigning roles as and when required. You can also test the process flow by running instances of the checklist and reviewing its performance metrics compared to an earlier iteration.

4. Set improvement goals

Goals are important to help you and your team keep an eye on where you’re going, as well as how far you’ve come on your OpEx journey. Your goals will become your milestones, helping your business mark its progress toward achieving Operational Excellence.

It’s important to make sure everyone has an opportunity to contribute to setting these goals, as well as achieving them. Implement metrics from your chosen methodology, and share appropriate information with your teams so they can see how near or far the organization is from its goals. You can access metrics from your teams’ Way We Do activity reports.

Some goals you may want to consider could be fewer compliance issues, reducing your carbon footprint, or boosting customer retention.

5. Execute improvement project(s)

Change can only happen once you’ve implemented your improvements and they’ve become part of the way your organization works. As you seek out ways to improve, it’s essential to test and validate your strategies. By carrying out small improvement projects, you’ll be able to validate your findings from your earlier analysis and execute improvement programs more effectively.

6. Assess impacts and start again

Review your projects’ successes and failures to determine your next move. Involve the appropriate stakeholders in your assessments to evaluate potential ideas for future improvements, and priorities for your following projects. This also gives you an opportunity to get stakeholder buy-in early in your improvement activities, and should always align with your improvement goals.

Remember, improvements are not one-off affairs. Reaching your expected state of excellence will require several iterations and actions before it becomes an ingrained part of your everyday activities.

Challenges of implementing OpEx

We know that when appropriately implemented, OpEx sets your organization for growth but getting there won’t necessarily be a walk in the park. You can expect to face these three key challenges as you implement your new OpEx strategy.

1. Getting your OpEx strategy to align with your operations

A clear set of objectives is the most fundamental prerequisite for a successful organization. Your daily operations – the work your employees carry out every day – are what help you achieve those objectives.

To demonstrate excellence, your strategy must align with your operations. However, businesses often struggle to align the two. While it’s easy to create new processes, if you don’t consider the overall business strategy, you and your team might find yourselves generating results for the wrong things. Any new processes, continuous improvement efforts, or OpEx implementation must be in harmony with your business objectives if you’re to achieve real transformation.

2. Lack of systems to identify improvement opportunities

Systems, processes, and quality information are too often non-existent in most organizations. You can’t carry out discovery activities and analyses when processes only exist in someone’s head, or in a system that’s not accessible to the users. Similarly, you can’t improve or review processes that aren’t properly documented.

3. Internal resistance and fear

Successfully implementing an OpEx framework changes an organization’s culture. Of course, humans are notoriously difficult when it comes to change, and you’ll be met with some level of resistance and/or fear if your employees don’t understand the change, or the value it can bring to them, the business, and the customer.

Your teams are the heart of your operations, and it’s important to engage them with exercises that will improve the organization for the better. A good strategy for overcoming their resistance and fears is by sharing your reasons for embarking on this journey, your objectives, and how it will help the business. Helping your employees understand the crucial part they play in the project’s success will build a sense of belonging and ownership of outcomes.

Keeping the OpEx momentum going

OpEx is a mindset every ambitious business should strive to establish as part of its culture. It can play a fundamental role in building business resilience – something we’ve all come to realize is crucial to staying successful in an increasingly challenging and competitive market. OpEx isn’t just a one-off exercise. It’s a way of life for your business.

Here are six critical activities you need to stay on top of to keep your OpEx momentum going over the life of your business.

1. Keep your operational processes up-to-date

Review your processes regularly and implement any improvements immediately so you reap the benefits as soon as possible.

Your documentation is where you’ll identify process improvement opportunities and monitor performance. Discourage paper-based documentation and reporting – things can be forgotten, reports may not be comprehensive, real success isn’t calculated, and paper is static. Think of your organization as a living being, and your processes the steps your team takes to keep it alive.

Way We Do encourages you and your team to actively use your processes, and the platform’s dynamic prompts help make sure information is accessible to the right people at the right time.

2. Maintain management buy-in at a constant level

OpEx imbibes an attitude of getting things done right, first time, in every member of your organization – from front line staff through to senior management. As your organization’s leaders, your management team must champion your OpEx movement and keep it on course. It’s deceptively easy to slip back into old habits, which can quickly negate all your efforts so far.

3. Recognize staff contributions

When you’ve worked hard and hit your goals, it’s important to share successes and reward your teams for a job well done. A culture of encouragement cultivates a sense of empowerment in your employees and helps them grow personally as well as professionally. A great way to reward staff is by giving them opportunities to develop their competencies further, and take on added responsibilities.

4. Integrate improvements

Integrate successes and improvements into your organizational culture and the way you and your staff work. It’s not enough to acknowledge them. To fully embed your gains as sustainable practices, it’s important to keep raising works standards. Or in the words of Shingo: “seek perfection”.