Six Sigma research tells us that many processes before being optimized only provide less than 5% of value-added activity. This means that up to 95% of processes contain non-value added activities and rework that may be wasting valuable resources in your company or organization.

The goal of business process management is to optimize processes and to eliminate waste.

There is likely to be wasted resources and efforts in your organization that you maybe unaware of, or that the process has become an engrained way of doing things, that it has become accepted and no longer obvious.

If you were to eliminate these wastes, could you generate more profit and deliver products and services faster to market?

If your competitors removed these wastes, could they offer the same products and services you offer, but at a lower price to the customer?

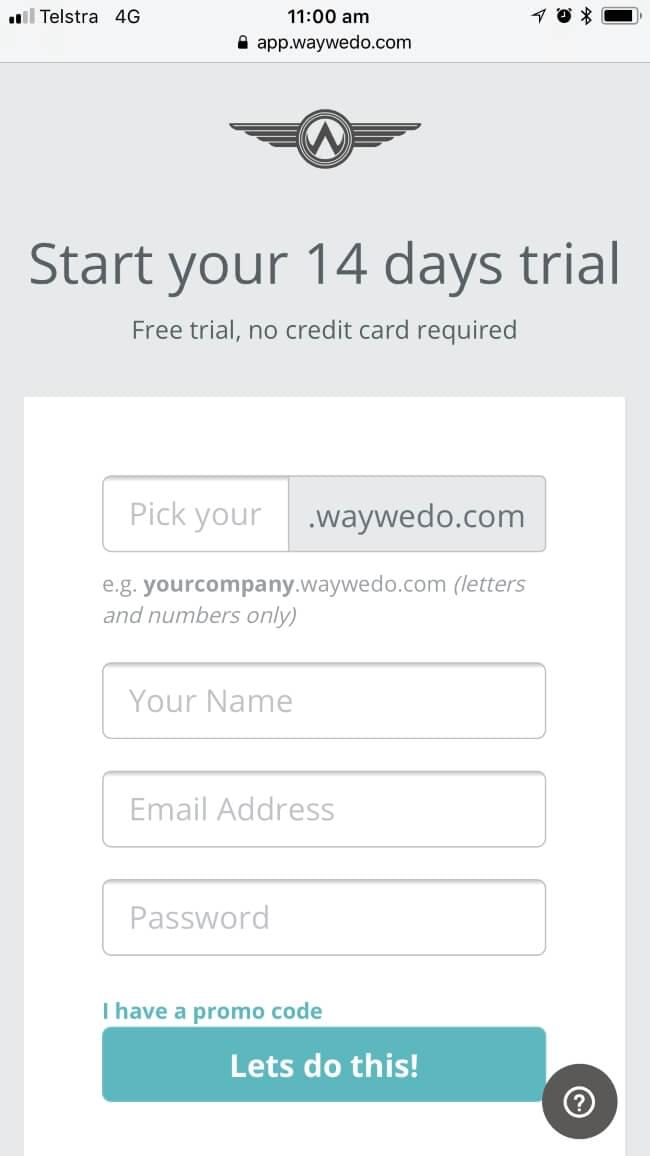

Why you need Way We Do now…

Over Production

Are your processes allowing you to create excess units or providing more to the customer than what they need or are willing to pay for?

Defects

Are your processes generating Rejects, Repair, Rework and Returns? How much is this costing your business? Is this impacting customer retention? Often, defects cause a lot of confusion and delays, and may cause customers and employees to look elsewhere.

Transportation

Is the direct or indirect movement of people, products, materials and information going from one step to the next be causing unnecessary costs? Transportation wastes can happen on the manufacturing floor, or in electronic processes in the corporate office to name a couple of examples.

Waiting

Does waiting for parts, materials, information, instructions, approvals or equipment adding costs to your processes?

Inventory

How much of your working capital is tied up in purchasing parts and materials before a customer has paid? While buffer stock can reduce cycle and lead times, excess inventory ties up cash, and can create extra handling and storage costs that may not be recovered.

Motion

Is excess motion involved in adjusting a machine, making reservations, or framing a house for example that could be done better by rearranging people, tools and layout, be costing your business more than what it should?

Excess Processing

Is your team performing tasks that are not necessary to the production and delivery of work within your business? e.g. polishing or sorting parts that don’t need polishing or sorting, using excessive product, overheating or over air-conditioning buildings, excessive lighting, redundant paperwork. Do your systems not integrate or talk to each other?

Skills

Are you under utilizing capabilities of your employees or resources, or delegating tasks with inadequate training?