Over-production is most common in manufacturing industries, but this type of waste can be seen in any business that provides physical materials for consumers. Some reasons that over-production occurs are:

- Poor automation processes

- Producing “just in case” stock

- Producing to forecasted needs rather than actual needs

- Poor communication and tracking

- Unclear expectations of customer needs

What Over-Production Looks Like

Though high production rates are often seen as a good thing, that is not always the case. Any time workers are regularly producing without regard for end need, there is a danger of over-producing. This can be seen in any industry, and in any part of your business. Here are some examples of how it may look:

- Manufacturing more goods than are needed

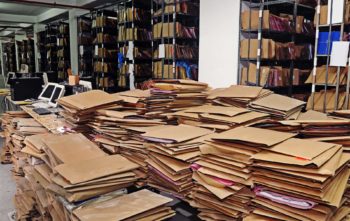

- Generating and printing documents before they are needed

- Producing components at different rates than finished products can be assembled

- Growing or cooking more food than will be consumed

When too much product of any kind is generated, it needs to dealt with in some way by business owners and staff. It may be stored, inventoried, tracked, moved, disposed of, or, in worst case scenarios, lost. This results in extra labor and costs for your business and a reduction in overall profitability.

The Solution

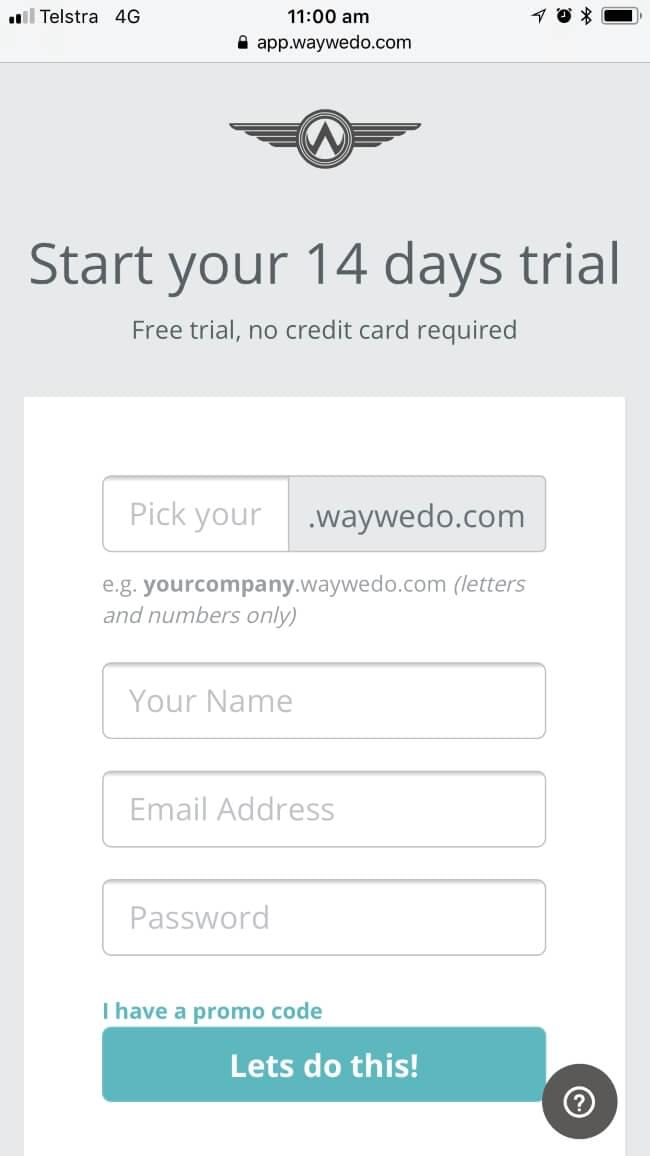

The solution to over-production is establishing better processes and workflows. It is important to keep up with demand without overdoing it, so creating processes to track customer needs and production times is crucial. You should also make concentrated efforts to systemize workflows so that every part of the business runs smoothly together, and create communication systems that eliminate bottlenecks at certain points of production.

The following suggestions can be adjusted to suit any working environment:

- Create and use checklists to ensure that customer need criteria is met before goods are produced.

- Provide clear procedures for tracking customer needs and buying trends.

- Track and monitor production times and production rates to ensure steady workflows.

- Create processes to analyze and minimize areas of overproduction. Keep your team informed of buying trends and communicate frequently about changing production needs.

Learn more about the potential wastes in your business by reading the previous post in this series: The Waste of Defects, and the next post: The Waste of Waiting.