The quest for continuous improvement and sustainable growth is the holy grail of today’s competitive business landscape. There are two models for addressing this: both widely employed; both rooted in process improvement and quality management. SDCA and PDCA offer unique perspectives for organizations that want to make more effective decisions and streamline their operations.

What are SDCA and PDCA?

These terms are initialisms of Standardize–Do–Check–Act, and Plan–Do–Check–Act. Each has its ideal application, depending on the industry the business operates in, and the outcomes they’re seeking to achieve.

Standardize–Do–Check–Act (SDCA)

SDCA is a systematic approach designed to establish and maintain standardized processes within an organization. Each letter in the term represents a distinct stage in its approach.

- Standardize – This involves creating and documenting standard procedures and best practices. Its aim is to eliminate variations and ensure a consistent approach to work.

- Do – This is the stage where an organization puts the standardized procedures into practice. It involves executing the processes as they have been documented.

- Check – This stage involves regularly monitoring and evaluating the processes being implemented. It helps identify any deviations and discrepancies, as well as any areas for improvement.

- Act – This stage uses the information generated from the Check stage to identify and implement corrective actions. Actions may include modifying the standardized procedures, or giving employees additional training.

SDCA emphasizes maintaining consistency and stability in processes. For this reason, it’s particularly useful in situations where adhering to established standards is critical, such as in manufacturing or other regulated industries.

Plan–Do–Check–Act (PDCA)

This approach is also known as the Deming or Shewhart Cycle. PDCA is another four-stage cyclic methodology that’s widely used for continuous improvement and problem-solving.

- Plan – This involves identifying a distinct process and developing a plan to improve it.

- Do – In this stage, the organization implements the plan on a small scale to test its impact.

- Check – This stage is about gathering data from the test and analyzing the results.

- Act – This stage takes the results from the test and either returns to the Plan stage, or implements the plan on a wider scale as it continues to monitor and analyze results.

The PDCA approach encourages iterative cycles of planning, execution and reflection. This makes it an ideal approach for process improvement, solving problems, and supporting innovation across a range of industries.

Standardize and map your processes with Way We Do. Sign up to a free trial.

The Differences Between SDCA and PDCA

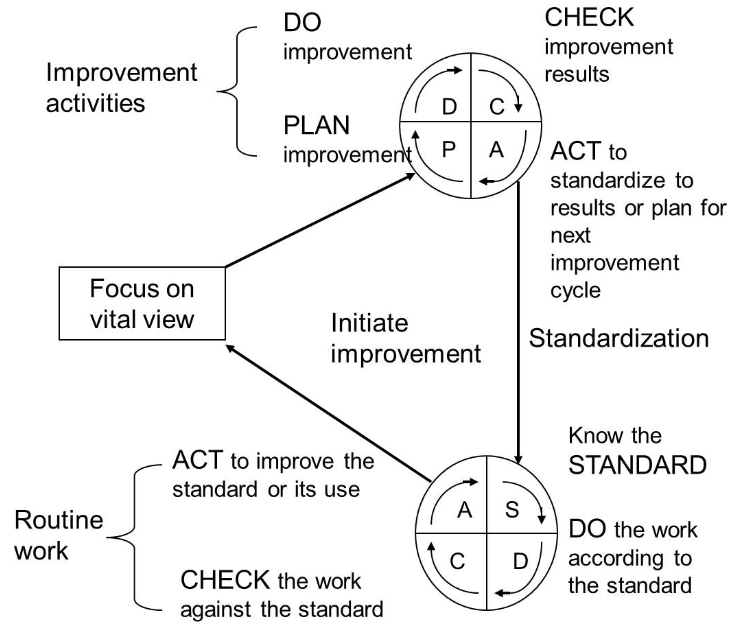

While both SDCA and PDCA share the goal of process improvement, they differ significantly in their approach and application. SDCA is best suited for stable processes that can be standardized and require control for consistency. In contrast, PDCA is primarily used for problem-solving and improvements in unstable or uncontrolled processes.

Essentially, SDCA is a stabilizing method to ensure processes are predictable and repeatable, whereas PDCA is a creative method aimed at innovative changes and improvements. In applying these methodologies, organizations should first look to SDCA to bring stability to their processes, then employ PDCA to make improvements within that more stable context.

Source: Seven Steps

Why use SDCA and PDCA?

Both SDCA and PDCA methodologies offer multiple long-term benefits to businesses that apply them.

- Improved process efficiency. SDCA and PDCA can help your team identify and eliminate bottlenecks, resulting in smoother, more efficient operations.

- Enhanced quality control. The regular checks that form part of SDCA and PDCA help you maintain standards and create more opportunities to introduce new ideas and improvements to your operations and offerings.

- Greater employee engagement. Involving your team members in solving problems and identifying ways to improve the business promotes a stronger sense of connection with and engagement in the business.

- Sustainable growth. The cyclical nature of both models means continuous improvement can live up to its name, and help businesses adapt and evolve in a way that supports its long-term survival and prosperity.

Implementing SDCA and PDCA with Way We Do

Managing change and implementing continuous improvement methodologies like SDCA and PDCA can be challenging without the right tools. That’s where platforms like Way We Do come in. As a leading cloud-based Process Management Platform, Way We Do is a game-changer when it comes to implementing and managing SDCA and PDCA cycles in your business.

SDCA Implementation

In terms of standardization, Way We Do provides a platform for businesses of all kinds to document, manage and distribute standard operating procedures (SOPs) throughout their organizations. With Way We Do, you can document best practices, work instructions and processes in a single location that’s accessible to everyone on your team. This not only supports consistency in how work is done in your business, but also enhances communication and reduces errors.

Way We Do supports the Do stage of SDCA by giving employees easy access to SOPs that help them complete tasks and follow workflows consistently and successfully. Way We Do supports the Check stage by letting you monitor how well your team members are adhering to processes. It also lets you track performance. process adherence and track performance. At the Act stage, Way We Do provides a framework for capturing feedback so leaders can adapt and refine processes, procedures and training based on real-world experiences.

PDCA Implementation

When it comes to PDCA, Way We Do gives organizations a platform to brainstorm and document improvements. Way We Do makes the Do stage more manageable, allowing for small-scale changes to be rolled out through revised SOPs, processes and workflows.

Way We Do’s reporting and analytics tools come into play in the Check stage, providing valuable data on how well the changes are working. Organizations can make data-driven decisions during the Act stage, and determine whether to adopt the changes more widely. They can then update the processes and SOPs with a few clicks.

Way We Do is an excellent means of promoting engagement and collaboration in the workplace, by creating scope for employees to contribute ideas, provide feedback and participate in the process improvement cycle. This fosters a culture of continuous improvement and innovation.

Embedding change

SDCA and PDCA are powerful frameworks for businesses that want to embed the principles of continuous improvement and sustainable growth. Whether it’s using SDCA to establish consistency through standardization, or driving innovation and problem-solving with PDCA, these methodologies have a place in every organization. Understanding how these approaches can impact your business and applying them using Way We Do can help you enhance your business’s operations, engage your employees, and boost your competitive edge.