Butter, an ingredient every household has, there’s a reason that the phrase “it’s the bread and butter…” exists. Who would’ve guessed that such a staple product could be the catalyst for a worldwide superstore ending up the focus of a media hurricane. As part of its recall management process, Costco recently pulled nearly 80,000 pounds of its Kirkland Signature butter from shelves. The reason? A missing ingredient on the label… “Contains Milk”!

Now, to the average person it may seem like an obvious ingredient that is present in butter, however, it is one of the “Big Eight” common food allergens: milk, eggs, fish, shellfish, tree nuts, peanuts, wheat, and soy, causing this overlooked detail to have the possibility of causing serious harm to those that rely on the wrapping to get allergen information.

Although this recall was conducted as a precautionary measure conducted by the U.S. Food and Drug Administration (FDA), and there have not been any reports of illness caused by the error, demonstrating another case of a corporation letting quality management take a backseat thus causing negative affects such as loss of customer trust and PR struggles to the brand’s name and image.

This butter blunder does highlight the necessity of recall management procedures being in place, how strong policies and procedures can minimize the hassle of these errors. Costco’s handling of the situation showcases the importance of effective communication. By promptly informing consumers and retailers about the recall, they ensured that the affected products were removed from shelves quickly. This transparent approach fostered trust and minimized any potential negative impact on their brand reputation. But remember, this error could’ve been avoided in its entirety if there was just a little more attention to detail and quality management of the product.

To prevent such incidents, companies should implement a robust quality management system. This system should include:

- Strict Labelling Procedures: Clear and detailed guidelines for labelling products, with regular audits to ensure compliance.

- Effective Supplier Management: Strong relationships with suppliers and regular assessments of their quality control processes.

- Robust Recall Management Process: A well-defined process and procedure for handling recalls, including swift communication with regulatory agencies and consumers.

- Continuous Improvement: Regular reviews of quality control processes to identify areas for improvement.

We often associate product recalls with food items, but the reality is far broader. Recalls can impact a wide range of products, from electronics to children’s toys to household goods. A recent example is Kmart Australia, a shop known as THE place to find affordable products of many categories, had to recall a toxic Christmas-themed quilt, ruining the holiday spirit for many customers that were just trying to add a festive touch to their residence. These seemingly harmless products were found to contain harmful substances, leading to respiratory issues and skin irritations among consumers. This incident underscores the critical importance of stringent quality control measures across all industries and a quality recall response.

When the recall plan for a company is ineffective, the results can be catastrophic; the 2008 Hallmark/Westland beef recall, one of the largest in U.S. history, had devastating consequences for the company. The recall, triggered by allegations of animal cruelty and improper slaughterhouse practices, led to the removal of over 143 million pounds of beef from the market. The financial burden of the recall, coupled with legal costs and damaged reputation, ultimately forced Hallmark/Westland into bankruptcy. This case serves as a stark reminder of the severe repercussions that can arise from weak quality control and a lack of planning for the chance of a product recall, but the list goes on.

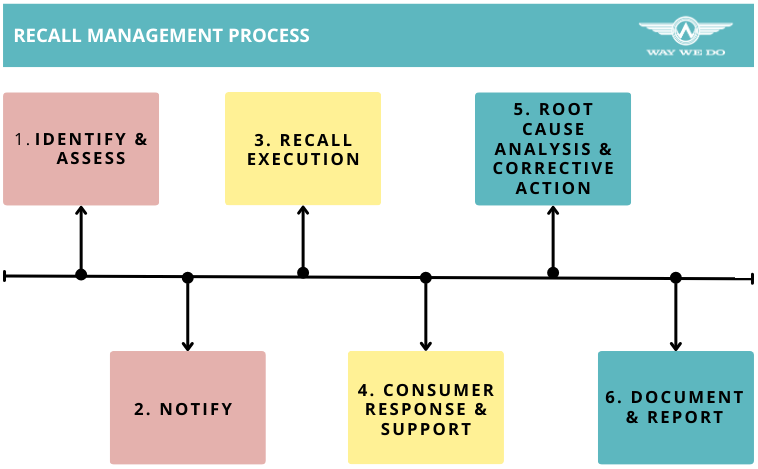

What are the key components of a Recall Management Process?

A product recall is a serious matter that requires a well-structured and efficient response. The 6-step recall management process provides a framework to effectively handle recalls, minimizing risks and protecting consumers. By following these steps, businesses can navigate the complexities of a recall and maintain their reputation.

Step 1: Identification and Assessment

- Identify the problem or defect that necessitates a recall.

- Assess the severity of the issue and potential risks to consumers.

- Determine the scope of the recall, including affected products and batches.

- Notification and Communication:

Step 2: Notify relevant regulatory agencies (e.g., FDA, CPSC) about the recall.

- Develop a communication plan to inform consumers, retailers, distributors, and other stakeholders.

- Create clear and concise messages about the recall, including the reason, affected products, and necessary actions.

Step 3: Recall Execution

- Implement a strategy to effectively remove the recalled products from the market.

- Coordinate with retailers, distributors, and other partners to facilitate the recall process.

- Establish return and refund procedures for consumers.

Step 4: Consumer Response and Support

- Set up a dedicated customer service line or online portal to address consumer inquiries and concerns.

- Provide clear instructions on how to return or dispose of the recalled product.

- Offer appropriate compensation or replacement products, if necessary.

Step 5: Root Cause Analysis and Corrective Action

- Conduct a thorough investigation to determine the root cause of the issue.

- Implement corrective actions to prevent similar problems in the future.

- Update quality control procedures and standards.

Step 6: Documentation and Reporting

- Maintain detailed records of all recall activities, including communication logs, product tracking, and consumer interactions.

- Submit required reports to regulatory agencies.

- Conduct post-recall evaluations to assess the effectiveness of the recall process and identify areas for improvement.

The specific steps and procedures may vary depending on the nature of the product, the severity of the issue, and regulatory requirements. Ensuring product quality and responding effectively to recalls is crucial. Way We Do offers a comprehensive solution to streamline these processes.

By centralizing your quality control policies, procedures, and recall response plans, Way We Do empowers you to:

- Enhance Efficiency: Automate routine tasks and streamline workflows, saving time and reducing errors.

- Improve Collaboration: Facilitate real-time collaboration among team members, ensuring everyone is aligned.

- Maintain Compliance: Adhere to regulatory requirements with a robust audit trail and version control.

- Protect Your Brand: Respond swiftly and effectively to recalls, minimizing damage to your reputation.

With Way We Do, you can establish a robust quality management system and be better prepared to navigate any challenges that may arise.